This spray pattern quick guide addresses common challenges faced by anyone who paints with an air assist spray gun. Check pressure control for smooth operation.

Techniques For Painting With A Sprayer Graco Homeowner

Moving gun too slow.

. Our North American headquarters is located in. Air holes clogged on air cap or air cap damaged. Increase or decrease the air pressure until even particle size is achieved.

One way to prevent problems with your spray gun. Motor is hot and Runs Intermittently. Turn material knob counter-clockwise to reduce flow.

Spray a fast test pattern on a clean sheet of paper and check the consistency of the particle size. Check that you are not leaning to far in a direction with the spray gun if your using a suction or gravity fed spray gun. Clean air holes or replace air cap.

Flush Flush before using the equipment before. Spray a fast test pattern on a clean sheet of paper and check the consistency of the particle size. Anest Iwata is a leading manufacturer of engineered solutions for air compressors vacuum pumps spray and finishing equipment.

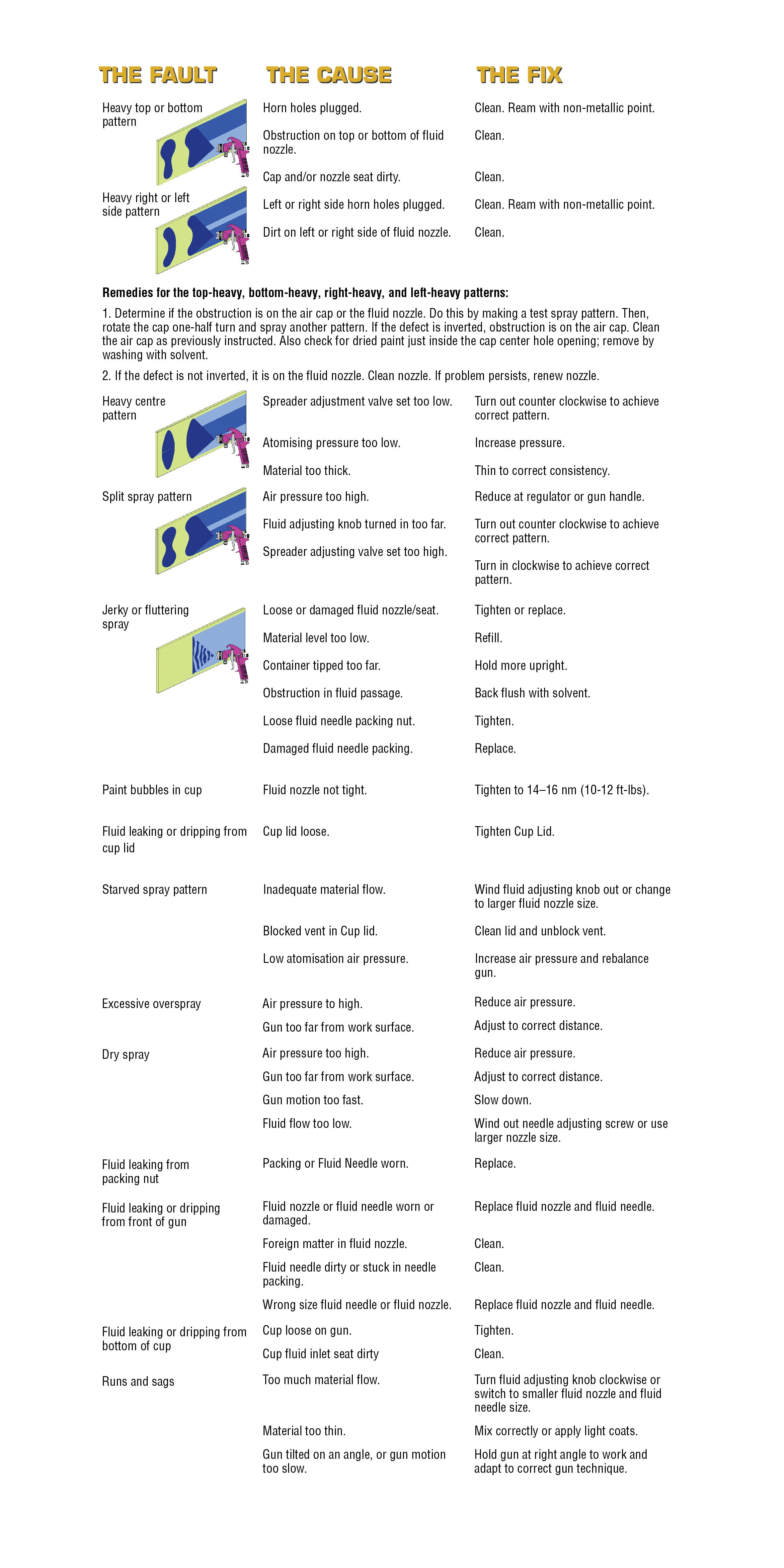

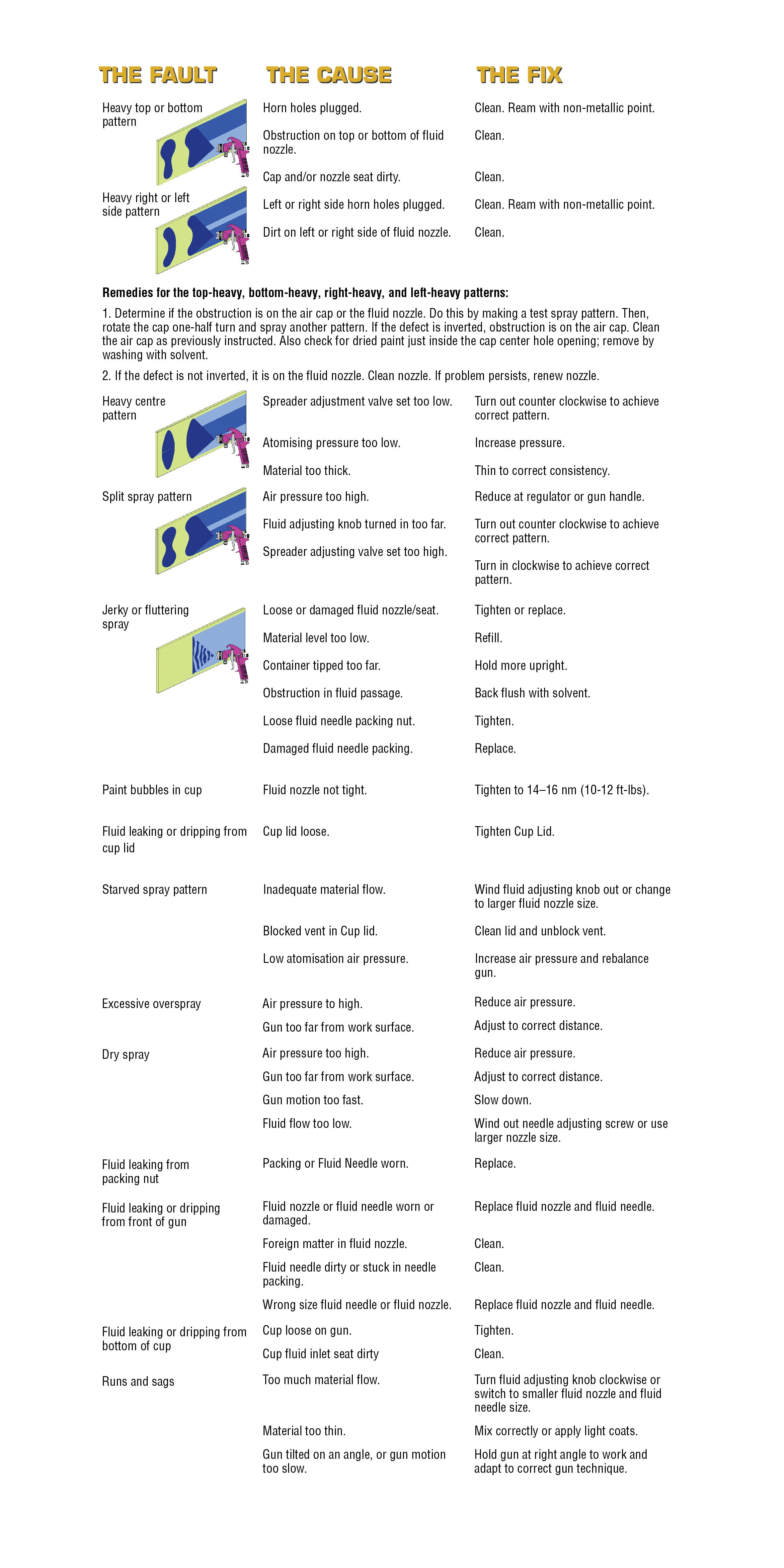

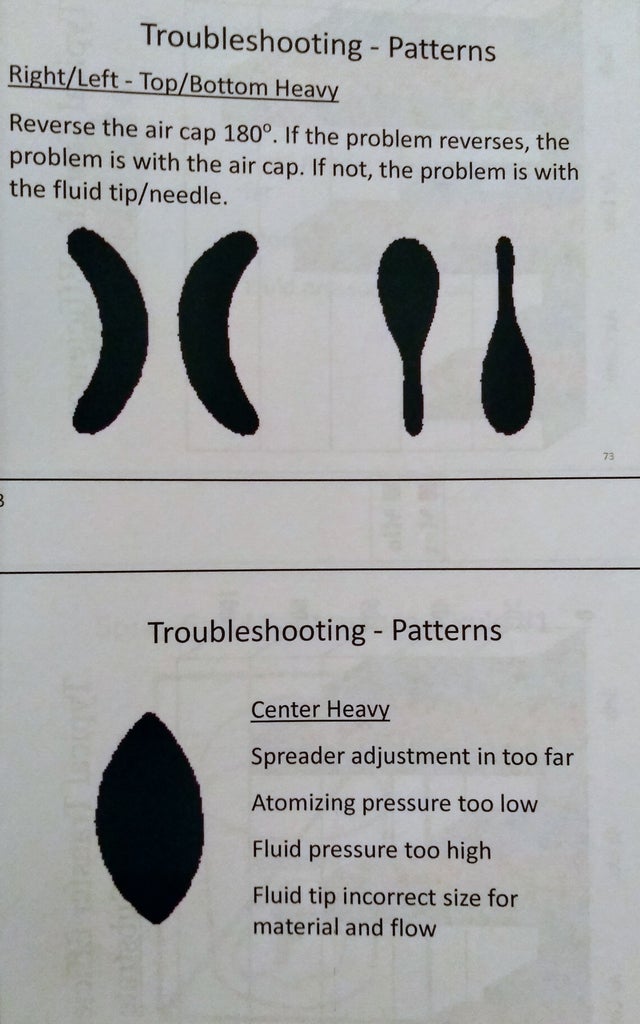

Bad spray patterns can be caused by several different things. Thin material per thinning instructions. MAINTENANCE TROUBLESHOOTING PAGE 2 SPRAY FAULTS Condition Cause Correction Improper spray pattern Gun Improperly adjusted.

Problem3 Jerky or fluttering spray. Increase or decrease the air pressure until even particle size is achieved. But it can be a bit intimidating as a beginner.

Reduce number of spray guns. Immerse only the front end of the gun until solvent just covers the fluid connection. HVLP Spray Gun Problem 2 My Gravity Gun is not getting any paint delivered to it If you are using a gravity feed HVLP spray gun and not getting any paint in your pattern this is most likely due to needing to thin your paint needing a larger fluid nozzle or needing to use a system that will force the material to the spray gun like a Dekups.

SOLUTION Adjust fluid regulator or fill fluid supply. Spray gun too close to surface. Use a bristle brush and solvent to wash off accumulated paint.

First make sure that your tip size is the right size. Do not submerge the entire spray gun in solvent because. Too much or too little pressure for your tip size and materials can also negatively affect your spray patterns.

Cause ①Insufficient material in the cup or. 1-Determine if the obstruction is on the air cap or the fluid tip. Next make sure youre using the right amount of pressure.

Then rotate the cap one-half turn and spray another pattern. Check low output section. Check to make sure you have sufficient material in your gravity or suction cup or in the pressure pot if not fill as needed.

Gun too far from surface. The spray gun is a key component to achieving an excellent Teflon paint or powder coating finish but spray guns are far from maintenance-free. Orange peel check the.

Cleaning your spray gun regularly is important to avoid slowdownsor stoppagesin production. Tighten fluid nozzle or replace fluid nozzle and needle. If your HVLP spray gun is spraying inconsistent patterns ie.

Turn the atomizaton air to about 30 psi at the gun. Clean Lubricate see lubrication section or loosen packing nut. Its perfect for doing faux metal or even just painting a straight color really fast.

When I was first starting out I couldnt find any. See Troubleshooting page 11 for informa-tion on how to correct the problem. Incorrect fluid delivery or viscosity.

If your paint gun is spitting or dripping paint it is probably because the nozzle is. If material is not fed into the gun it will cause a spitting pattern. Move gun closer to surface.

Tighten fittings or replace equipment as needed. Check for fluid leakage. Turn the atomizaton air to about 30 psi at the gun.

Check transducer for wear or damage. If one of the air passages become plugged the spray pattern is not going to spray evenly. Tighten or replace fitting.

Spray a horizontal test pattern holding the trigger open until the material begins to run. The lubricant in the leather packings will dissolve and the packings will dry out. Too much material flow.

Speed up gun movement. Lubricate or replace packings or tighten packing nut. Do this by making a test spray pattern.

Do not disassemble the spray gun if you are having a spray pattern problem. Spray a horizontal test pattern holding the trigger open until the material begins to run. Spray tip worn beyond sprayer pressure capability.

HVLP Spray Gun Problems HVLP Spray Pattern Problems. Clean the fluid and air line filters daily. If the pattern is heavy on one side or if the spray gun is spraying a half moon shape turn the air cap 180 degrees and see if.

Spray Pattern Troubleshooting Select the issue youre facing to see examples possible reasons the best solution and why it is important. Using a spray gun can give you a smooth as silk surface finish. Clean with soft implement or submerge in suitable solvent and wipe clean.

Troubleshooting Common Spray Gun Issues. A tip thats too large will cause issues with your painting pattern. Gun sprays sickle shaped to the left or right.

Dirty air cap Fluid tip obstructed Sluggish needle Readjust gun follow instructions carefully. This can result in uneven mill thickness stripes and dry edges.

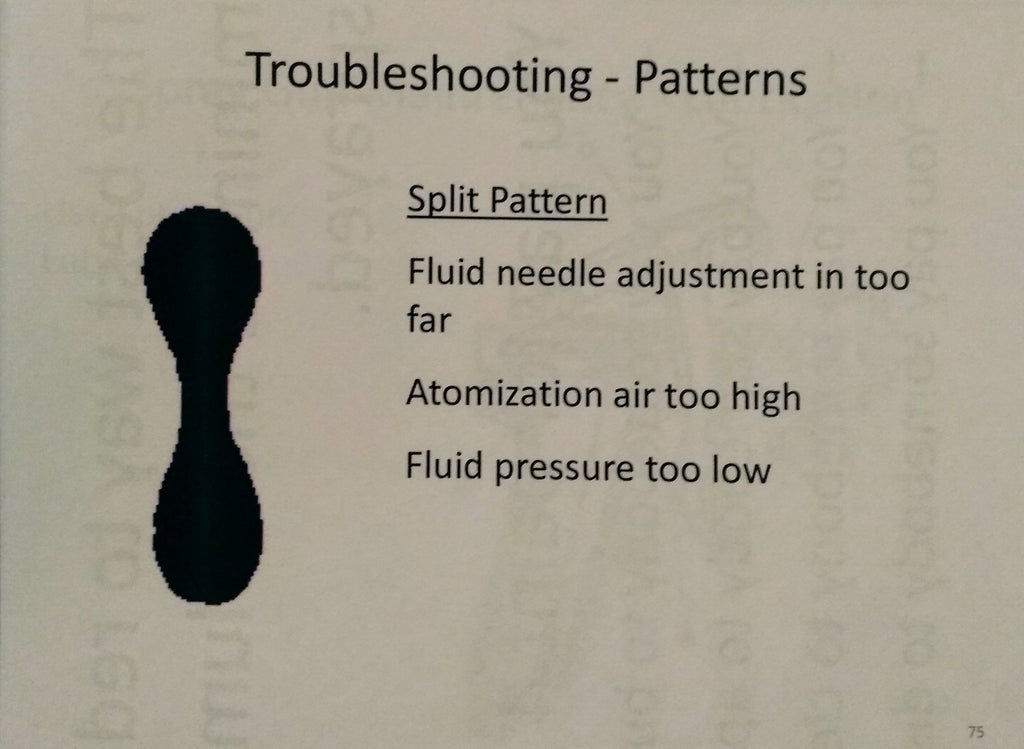

Respraying A Morgan Setting Up The Compressor And Spray Gun Trouble Shooting Spray Gun Faults

Devilbiss Hand Spraygun Troubleshooting

Troubleshooting For Spray Paint Gun Conditions

Spray Gun Troubleshooting Car Colour Services

Spray Gun Beginner S Guide 13 Steps Instructables

Auto Paint Sprayer Spray Gun Controls Car Paint Technologies Guangzhou Jinwei Chemical Co Ltd

0 comments

Post a Comment